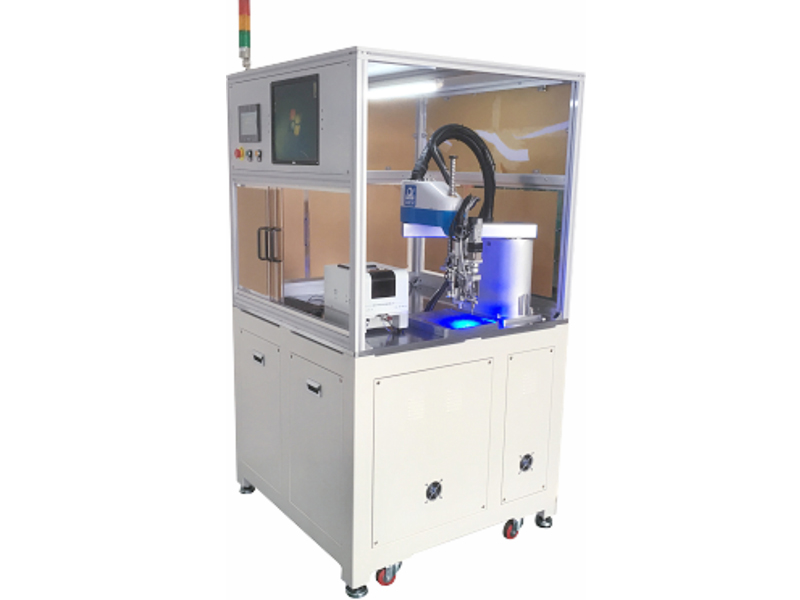

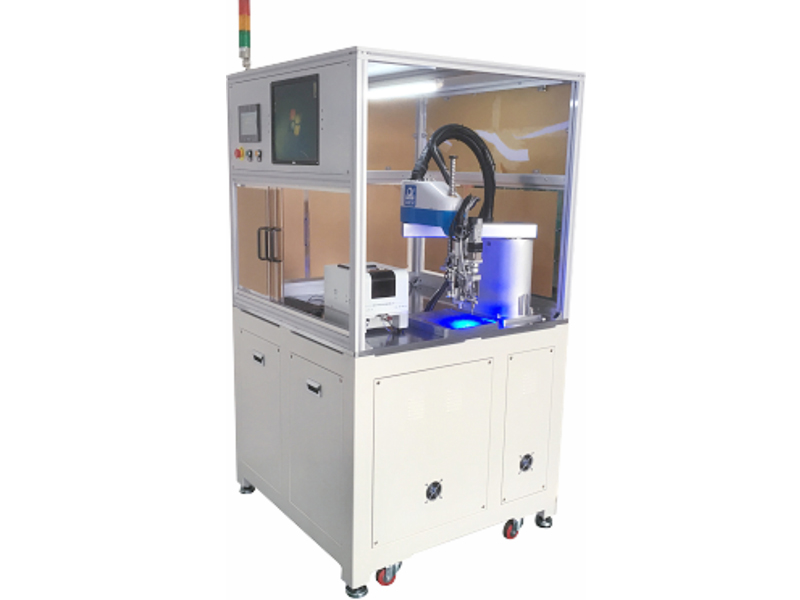

Robotic CCD Visual screw fastening station

On-line robotic visual screw fastening machine is an automatic working station, applicable to fully automatic production lines and can fasten the screws automatically, no labor needed. When the workpiece flows to the current station, the robot will start the visual system, take the pictures for the screws’ position, process the data of screws deviation, identify the workpiece and fasten the relevant screws accurately. This machine succeeds to achieve the goal of unattended work station.

Product detail

Robotic CCD Visual screw fastening station

Description

On-line robotic visual screw fastening machine is an automatic working station, applicable to fully automatic production lines and can fasten the screws automatically, no labor needed.

When the workpiece flows to the current station, the robot will start the visual system, take the pictures for the screws’ position, process the data of screws deviation, identify the workpiece and fasten the relevant screws accurately. This machine succeeds to achieve the goal of unattended work station.

Feature

- Applicable to any flow lines, no customization needed.

- Automatically visual positioning, no worries about the workpiece change.

- Visual positioning is more flexible and universal than traditional ways.

- Servo motor screw driver, EMS data recording system and every data is traceable.

| Parameters | |

| Arm Length | Full arm is 450mm long, axis A is 200mm long, axis B is 250mm long |

| Max Speed | Axis A+B 6670mm/s,Axis Z 1250mm/s,Axis W 1940mm/s |

| Work Space | Axis A: ± 135°B:± 150°Z: 200mm,W: ± 360° |

| Re-positioning Accuracy | Axis A+B: ±0.02,Z: ±0.01,W: ±0.01° |

| Max Load | 6kg |

| Weight(Body) | 33kg |

| Rated Voltage | 230V a.c. 50/60Hz |

| Rated Power | 1kw |

| Motor braking voltage | 24V a.c |

| I/O port | 12 paths universal digits input, 7 paths universal digits output (extendable) |