News detail

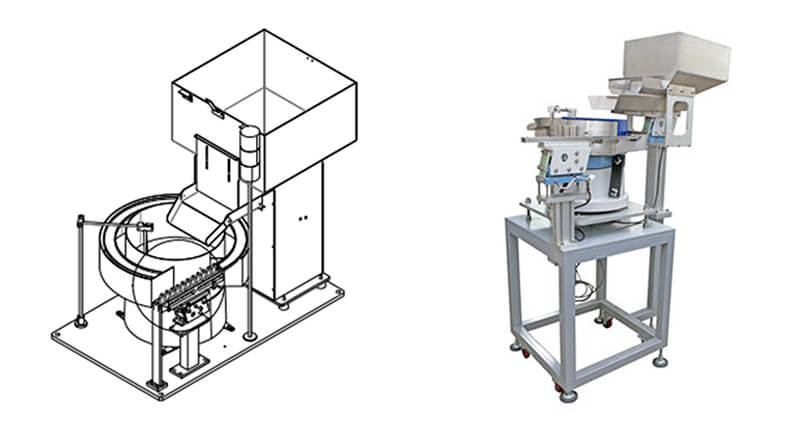

Newest feeding system: step feeder system

Step Feeders are perfect for gentle feeding and presentation of parts for automatic assembly, automatic inspection, automatic sorting, or secondary operations. These versatile step feeders are used heavily in the automotive step feeder industry and known for their gentle feeding, flexibility, efficiency, and day to day reliability. They are an especially popular option for feeding parts to centerless grinders.

This type of feeder is ideal for long cylindrical parts, such as bolts or rods. Parts are loaded into a hopper bin. Every other step is mechanically driven up and down, bringing parts to the stationary steps. In cases where multiple tracks must supply parts in a certain orientation, the parts will typically flood onto a long vibratory pan which transitions into several tracks. Over flow parts are able to fall off and slide back to the hopper bin. Step feeders are quiet and able to elevate parts, eliminating the need for a hopper elevator.

One Russian client needs a bowl feeder for thermocouples, according to their requirements and thermocouples size, we designed the bowl feeder with hopper and linear feeder, it matches two sensors, one is the full -material-stop sensor, the other one is bowl short material sensor, it can ensure the bowl feeder with high performance.